I, like many bikers, had the idea of one day doing a project bike. Every bike I’ve owned has been modified to my personal taste, this is my K1200R which was dead stock when I got it.

I had talked about wanting to do a proper build for some time. My very supportive, beautiful wife asked me what I was waiting for? I stumbled across the following bike on the BIKEEXIF and got motivated!

I was blown away that a K100 could look so good! This blog is how, over 4 months, I turned this;

Into this.

And after my mate crashed it, this.

I found the donor bike in Adelaide as an unregistered trade-in advertised on gumtree. My Dad and I did a quick 1540km round trip, and the real journey began!

Bought a bike lift off ebay.

Fairings and seat were stripped and sold to a wrecker for $450, No turning back now!

Being my first build, I’m still trying to work out the sequence of work. It is a bit daunting! I decided to start easy and do the front guard.

I marked out trimmed shape I wanted

and went at it with the dremel.

Have ordered 3M carbon fibre wrap to finish it off.

Dad did a good job of trimming unwanted metal tags from the subframe

I took a slightly different route for a radiator overflow tank!

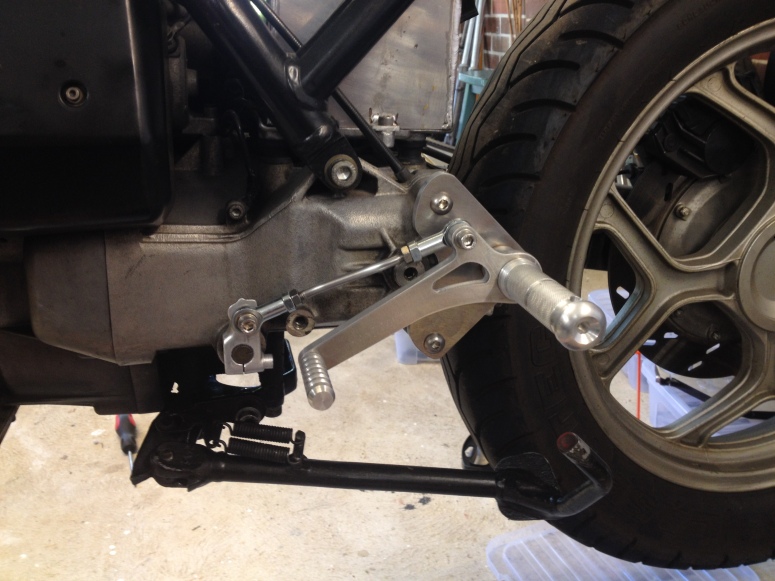

Pace should pick up now, the goodies that arrived this week; Rear sets from BSK SpeedWorks Speedo from Daktota Digital

The rear-sets were an easy fit, and very well made

Before

After

I was hoping the exhaust collector I found would be easy to rotate 90 degrees to get the angle I wanted. Not possible! It will only fit in the header pipes one way.

Have found Mick at Valley Engineering, who has modified it to suit.

He also has fixed the Clip-On bars, making the bars 22mm and the mounts 41.3mm. I’m getting a rough idea of the seat unit style I’m after. I want to follow the line from the fuel tank base through to the rear tail unit. I’m not after a particular style, but aiming for a look that is a cross between café racer and street fighter.

Clip-ons were an easy fit after mods to the bar diameter and fork clamp!

The Speedo mount is done. Longer brake hose fitted.

Lowered the speedo a bit, happy with it now

Decided to only use one horn. Made a bracket and mounted it on the left, behind the radiator.

Rear brake reservoir mounted.

Getting rid of the last of the frame tags.

Bike is now off to Valley Engineering for some surgery.

Mick (on the right) is going to do the tasks I can’t do at home.

– Hone out the hole in the upper triple clamp to hold the ignition block.

– Fabricate an exhaust hanger.

– Cut and brace the sub-frame.

– Manufacture the seat unit and tail piece.

Mick has form, turning his Ducati Monster SP into a café racer with the radiator moved to under the sub-frame!

One week later …………………………………………………..

Extra bracing of the sub-frame.

The smaller battery is now enclosed.

The ignition now fits in the clamp,

The seat unit is just how I wanted it. It continues the line from the tank, and the frame.

Fortunately, I provided accurate drawings, and a scale mock up to work from!

The exhaust is now finished!

The tank and seat unit are off again for painting. My mate Pete of Peter’s Panels has offered to do the job for a couple of bottles of scotch! On the condition I do the preparation work. The colour is from a new range called ‘vibrance’. It is a nod to the BMW 1970’s colours, but with metal flake.

I bought some bar end indicators off eBay to use in the frame holes. Internal wiring was an interesting job!

Front fender now covered with 3M carbon fibre wrap.

Battery connected and installed in custom made box.

Now for the part I’ve been dreading!

We have ignition!

I’ve managed to get most of the cautions working, I can’t get the neutral light working for some reason. I need the tank and seat unit back to run the engine to check tacho. Then to see if the OEM speedo signal will work……… nope!

I ended up getting a sensor unit from Dakota Digital and mounting it on the front wheel. It counts the wheel studs.

The master at work, putting on the base silver coat.

The paint job by Pete is flawless!

The wiring is coming along. Yellow spaghetti! Thank you self closing braided line!

I’m away for work the next week, will book in the seat fabricator when I return. Reassembled to get the seat done.

Got the seat back, great job! Put the bike together and added the headlight to preview the finished bike.

After 6 days work, back into the wiring. This is a boring picture, but it is satisfying to get it right. Now have a waterproof quick release connector for easy seat removal.

I later changed to a smaller, completely waterproof connector.

I took the tank and seat back to Pete for a final touch up today. Pete surprised me with a sticker he’d got made up. It turns out the colour I chose is called “hornet orange”. Since I flew hornets in the RAAF, Pete had the sticker made. The bike now has a name!

I’m now just waiting on a couple of 12ohm resistors from eBay. They need to be installed next to the flasher unit under the tank so the LED indicators work properly. While waiting I’ve changed the oil, oil filter, fuel filter, bled the brakes, and done some polishing.

I’ve got the indicators working, tank and seat back on. Given it a start up. Almost done!

After initial rough running and stalling (I think it was air in the lines due fuel filter change), it settled down and ran smoothly. The exhaust is surprisingly not much louder than stock! Programmed the gear indicator and calibrated the speedo. The weight loss was apparent from the first crank of throttle! It is a bit of a reach to the bars, but at 100km/h the weight comes off the wrists and it should be good for longer rides. I still have few things to do. The rear mud guard looks like it can be chopped into a small fly screen to cover the instrument wiring.

I have been a bit remiss by not acknowledging my co-builder, dad. He provided the workshop, tools, and lots of unwanted advice (some of which was useful)!

I did not like that the speedo wiring was visible (even though it was covered in black shrink wrap). The removed rear mud guard was made of plastic. I thought it looked about the right width. Cut to shape, then covered it in carbon fibre wrap. No more visible wires and cables!

I also took off the centre stand to tidy up under the bike.

The rear shock was on it’s last legs. Bit the bullet and installed a Hyperpro.

I took the bike to get the shock dialled in. Bad news is that it has lost so much weight I need a lighter spring! Going to get it resprung and revalved for the new weight.

Couldn’t only do the rear, so the forks are off for some White Power springs and oil change.

New springs and oil. I think I can now say it is finished! Cleaned up and ready to go.

I had been working towards entering it in a bike show in Melbourne called “Oil Stained Brain”. It turned out it did not make the cut, and I only finished it 2 days before the show. The weekend of the show, without a decent test ride, I took it on 1000km loop into the snowy mountains with some mates! The only glitch was having to tighten the folding mirrors when they folded back at 170km/h!

After the loss of weight, and suspension work, it was as fast as my K1200R in the tight stuff! I’m still tinkering. Was not happy with the quality of the mirrors, so have changed to these.

I finally took some photos with a real camera (instead of my phone).

I have found the rear indicators not bright enough in direct sunlight. Santa made a late delivery of these beauties!

Definitely bright enough!

The baby bottle idea for the radiator overflow turned out to have insufficient volume. I have replaced it with a 500ml stainless steel drink bottle.

The join between the steel collector and the aluminium exhaust has never been ideal, continually working loose due to different expansion rates. I think I now have a solution using a V-clamp. It also makes for easy exhaust removal (needed to remove rear wheel).

I took the opportunity to paint the header pipes black. The paint needed baking, so I used the BBQ.

All done!

I will take it on a decent test ride as the Hornet is going to Tasmania for a 7 day extravaganza the end of Feb!

The seat pan is attached to the frame by two pins at he rear, and one central bolt at the front. I have occasionally noticed a small amount of seat pan flex, which I have decided to fix. I found these plastic lugs in the cupboard (I can’t remember where they came from).

I drilled the centers so they would fit snugly onto the alan head bolts that hold the rear tank mount. I had to shape the tops to match the seat pan, then paint them black.

Rock solid now, ready for Tassie!

Day three of riding the great roads of Tasmania, my mate Kev lost the front end under brakes. The resulting low side caused too much to continue. Tank, engine casing, foot pegs, gear shift, left bar and switch block. I thought I had finished this blog, I guess not!

Shannons Insurance were great in getting it home, after several stressful hours when they were threatening to write it off and leave it in Tasmania!……………………

After recovering the bike to Melbourne, the Shannons assessor decided my poor bike was a write-off!

The good news is I’m going to fix it myself. I’ll take the opportunity to do some upgrades, stay tuned!! I’ve got my bike back in the workshop, build number 2 can commence!

THE HORNET MACH II

I considered repairing the bike back to pre-crash condition, but it seemed a waste of money and effort to do all the work and end with the same bike. Having learned so much in the first build, I thought about what I could improve. The bike was a weapon in the corners, but I never had much faith in the tires (Kev, even less so now!). To run radial rubber, wider wheels are needed. A K1100 wheel bolts easily onto the rear. I know it is possible to bolt on a K1100 front end, which gives 4 spot calipers. I thought, but why take the front end 5 years into the future, why not 20 years? Old bikes with USD forks also look the biz!!

I’ve sourced some parts. Found a decent tank for $150.

The Valve cover will require bead blasting.

I spent several hours at the wreckers looking for some USD forks in good condition. I needed a 3 spoke front wheel to match a K1100 rear wheel. The best solution was from a 2000 Yamaha R1. I put a deposit on the front end so I could take the triple clamps. I wanted to see if it was going to work before I paid the full amount!… I’ve got the triple clamps at Valley Engineering getting assessed for the transplant! The BMW post needs to be mated to the Yamaha clamps. If the R1 plan doesn’t work, I’ve sourced a BMW K1100 front end. In either case, I will need another solution to for the ignition key mount. I’ve decided to remove it from the triple clamp to clean up the dash. I was scratching my head for a mounting solution when I spied the surviving mirror from the crash….

Angle grinder and drill converted it to an ideal bracket for side mounting the ignition block!

The R1 clamps are now fitted to the BMW shaft. Not cheap, but bolted up perfectly! Will now collect the rest of the front end and see how it fits.

Like a glove!

Collected the engine covers after cleaning by sand rolling at Competition Coatings. He did the valve cover for free, to see if I liked the finish!

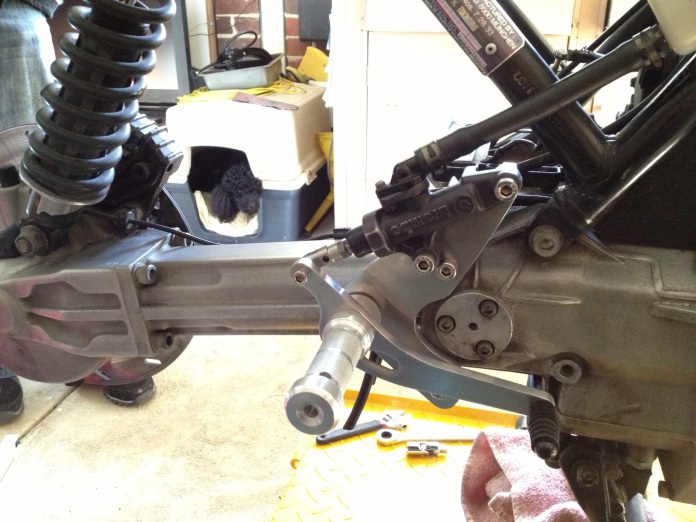

The new rear-sets have arrived, slightly redesigned, now with knurled levers instead of rubber. Nice!

I’ve used an angle grinder to remove the ignition mount and other tag from top triple clamp.

Will use a bench grinder to tidy it up….. All done, and sent to get powder coated.

The exhaust system is back after being ceramic coated front to back!

I’ll leave the can off for now, as the new wheel is still getting painted. The wheels are back from the paint shop. BMW K1100 rear, Yamaha R1 front, shod in Pirelli Angel GT tires.

Lisa, trying to distract me from those sexy wheels!

The rear bolted on no problem. Good clearance on both sides.

I used the damaged rear-set plate to fabricate the speedo mount. I had a small altercation with the bench grinder during the process!

Good result though, wanted it flush with top clamp.

Have decided to change the headlight to the MT-03 unit.

I like it, but will have to see bike complete to be sure.

A whole new throttle quadrant was required. The K100 master cylinder is 13mm in diameter. This is OK for the original brakes, but would struggle to operate the R1 calipers. A K1100 (20mm) master cylinder is up to the task, but can only be fitted by replacing the whole quadrant. This necessitated a throttle cable change also.

I was going to re-route the front brake line to keep the top clamp clean, but I like the K100 design.

The bar controls all done, just need to get some brake hoses fabricated.

I had to modify the K1100 hubcap to fit the K100 hub. Found the carbon fiber badge on eBay.

A rat tail file allowed the headlight bracket to take the indicators.

The front end is now complete!

I got the tank and seat from the paint shop today. The paintwork is exceptional!!

The fuel pump mount was broken in the old tank. A new part tomorrow, then final assembly……..

I was concerned the modern front end might not flow visually into the rest of the bike, but I couldn’t be happier!

I used the remains of the bent gear shift as a stopper so the stand doesn’t hit the exhaust.

I took the bike for it’s first proper ride through the hills yesterday. With the new front end and Pirelli rubber, it now feels like a modern sports bike. It is much more planted to the road, and the brakes are now comparable to my K1200R. I can now say the blog is complete (17-05-2014). The rebuild took just under 2 months.

Thanks for checking it out! It has now featured on The Bike Shed, twice, Pipeburn, and Silodrome.

I was also contacted by BMW Australia who featured it on their website, then I was incredibly stoked to have it feature on the international BMW Motorrad website!

My bike was accepted into the 2014 Oil Stained Brain bike show.

I finally got around to weighing it!

It now weighs 215kg fully fueled. Stock bike is 249kg, so it has lost 34kg. Distribution is 51/49 front/rear.

UPDATE

I haven’t updated this post for a long time now. After 4 years of trouble free riding, I’m considering letting the Hornet go. If you are interested, drop me a message.

Hi Paul, just wanted to say massive congrats mate she’s such a clean looking build. Awesome page with lots of helpful info, I’ve just purchased a 94 k1100LT to start my cafe dream in Melbourne and have already got a few good tips from here so thanks 🙂 One quick question I’ve been trying to find an answer on and you may know it is when you cut and shorten the rear loop did you need an engineers certificate for rwc in Vic? Thanks for any info you can provide in advance

Cheers

Scott

G’day Scott, unfortunately you’ll have to engineer the frame chop. Good luck with the build.

Thanks for getting back to me. I thought as much will look into it

Hey Paul.

Any recommendations on electrics? Mainly, what to keep, what to get rid of and what to replace with?

Love the hornet build. Looking to put a more modern front end on mine too.

Thanks

Hi Bonny, replacing the instruments is a bit of a pain. There is circuitry in the original housing for fuel level and neutral light that means you lose these features. If I were to do it again, I would do what I did Mitch the Kawasaki, and retire completely with Motogadget.

Thanks.

I found some posts of yours on the K100 forum. Taking your advise and going with the morogadget. Funnily enough the only speedo I like is the same Dakota speedo you’re using. I know I’m in for a world of pain with that one but I figured pairing the m-unit with the brotbox from Maru-labs might give me half a shot.

Any tips on getting it configured would be great. I’ll order the Dakota sensor too.

Hi Bonny,

Sorry, forgot to reply. The Dakota should work easily with the m-unit. Best to draw a wiring diagram before you start. I did one for the Kawasaki which you can find in my blog.

Paul

Hi Paul, can you give me info on the installation of the R1 folks pls? Is there a specific year the R1 triple tree will fit straingt onto the K100 frame with change to bearings. Thanks. Ady

Hi Ady,

I took both the BMW and Yamaha triple clamps to the engineering firm I use (Valley Engineering), and asked if it was possible to mate the Yamaha clamps to the BMW post. It was not a simple job as the BMW post was a slightly smaller diameter. The Yamaha clamps needed to be drilled out so a plug could be welded in, which was then machined to the correct diameter for the the BMW post to be pressed in. The upper clamp had to be modified to suit the the top bearing nut (the knurled one that covers the top bearing). All this cost $650. He just charged me his $100 hourly rate. These guys are a heavy industrial firm, not bike builders, so it was a bit of a voyage of discovery for us both! The price you pay could vary a lot.

Paul

Thanks for the reply Paul. I have been informed that the 2004/06 R1 triple tree is a perfect fit with K1 to R1 bearing conversion. I will explore this option further. Cheers.

Is there a reason why you got the exhaust system ceramic coated the second time instead of doing what I assume is powder coating like the first time?

Hi Eric,

Powder coating is ok for the muffler, doesn’t last on the headers due heat. Ceramic looks better and lasts. It is a bit more expensive, but worth it in my opinion.

Paul

That’s what I figured (did more research afterwards)

Thanks a lot for the fast answer

Hello Paul

like the beemer and love the R1 front,what have you done to fit it on the k100

grt frank

Hi Frank, please look through the comments section. I have addressed this there.

Hi Paul, gotta say it is a very impressive build, what a great achievement, I remember photographing this at Oil Stained Brain. I have been looking around Melbourne to no avail trying to find someone to build me a similar bike, would you consider building another similar? would love to discuss the possibilities

G’day Craig,

Thanks for the compliment! Sure, I’d be interested to discuss possibilities with you.

Give me a ring and we’ll have a chat.

Paul

0418885646

Goodday,

How did you fix the new radiator overflow tank? How do the hoses fit and do you have een overflow for the overflow tank? Just to the ground or something?

Thanks in advance

Hi, if you review the blog you will see I a photo with the overflow tank. I used gas fittings to plumb the line into the bottom of a aluminium drink bottle. The capacity of the larger bottle meant it did not need an overflow.

Ah great! thanks a lot!

Hi Paul,

My son and I think the Hornet looks terrific! We like how all the lines flow from the tank to the seat/cowl and tailpipe. My son is in the Navy ROTC at Pennsylvania State University. He wants to be a pilot as well. He bought himself a 1990 BMW K75 two months ago and is about halfway through the build. We are at the seat/cowl design stage. We’ve looked at many different designs on-line for the rear seat/cowl shape and we think yours looks the best and we’d like to try to copy it. You mentioned that you had created specific drawings for the seat/cowl. Is there any way that we could get a copy of your drawing(s)?

Thanks and keep up the excellent work.

Hi Bryan,

My best wishes to you and your son, fighter flying is the best way to spend your youth, I hope he gets to experience it!

Unfortunately I only did the rough sketch and the model made out of plastic chopping boards. My fabricator was a mind reader and able to create what was in my head from the drawing, model and discussions. The most important design element in my opinion is that the line running from the bottom of the tank must line up with the top of the tail unit. I used a broom stick to make sure this occurred with the plastic model. Without that the tail unit would look out of place, it works even though the tank is rounded and the tail is angular. I can provide measurements of the tail unit if you wish, but you can probably work it out from the photos.

Best of luck with the build,

Paul

Thanks for the reply. I agree with you that the line from the bottom of the tank should line up with top of the rear cowl. You do have a good number of photos in your blog that should help us get really close to your tail design. Also, I don’t recall if you mentioned it in your article, but what exhaust pipe did you go with? It looks sharp.

Thanks again,

Bryan

The muffler is a Supertrapp from the USA. Can’t remember the model.

Ok thanks. We’ll take a look at that brand.

Regards.